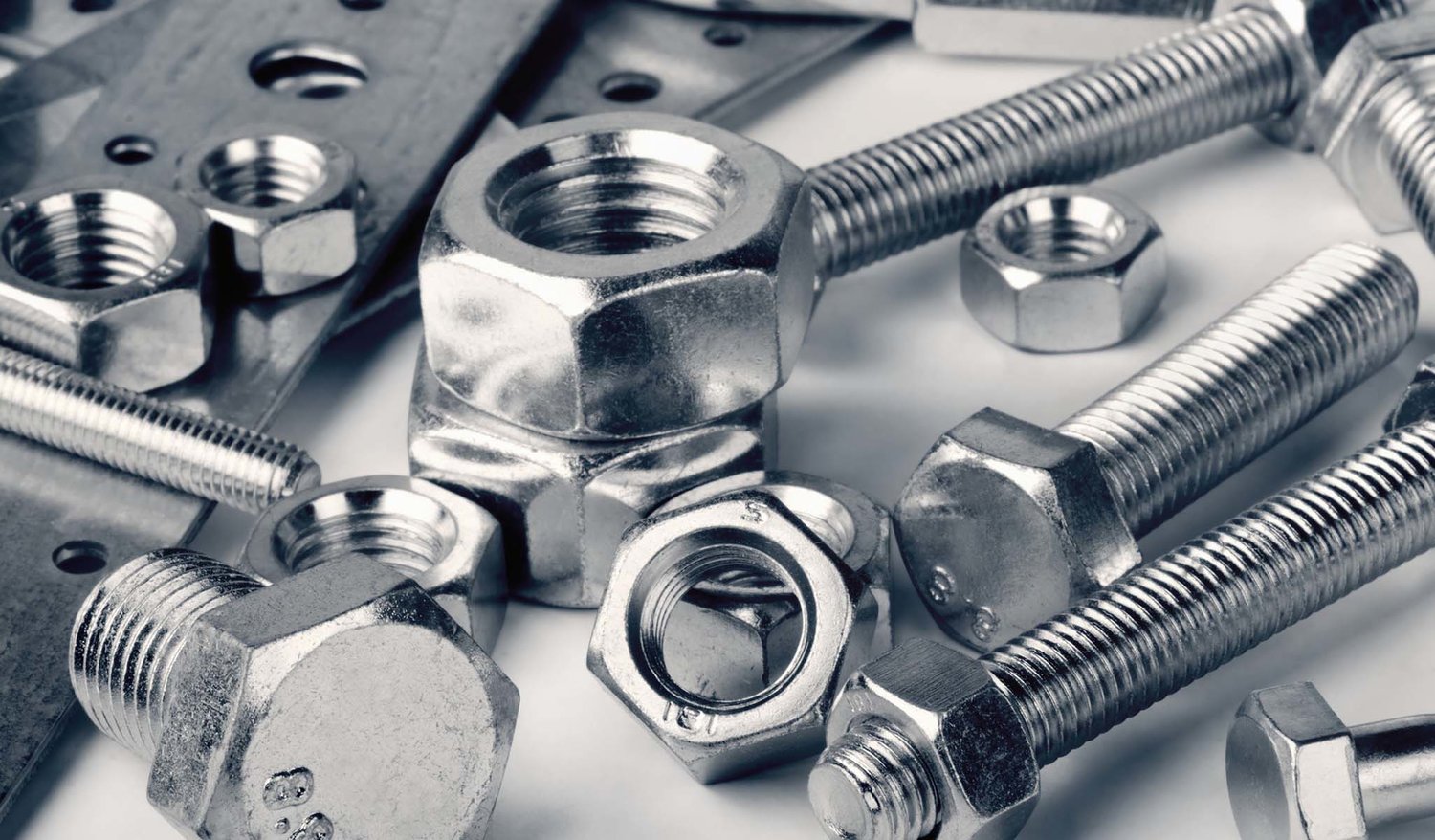

Stainless Steel Fasteners: Revolutionizing the Petrochemical Industry

The petrochemical industry operates in some of the most demanding and corrosive environments, necessitating materials that can withstand extreme conditions while maintaining structural integrity. Introducing stainless steel fasteners has ushered in a transformative era in the petrochemical sector, reshaping processes, safety standards, and reliability. Let’s explore how stainless steel fasteners have become a game-changer in the petrochemical business.

Corrosion Resistance in Harsh Environments

Stainless steel fasteners are renowned for their exceptional corrosion resistance, making them a natural fit for petrochemical applications. These fasteners excel in environments exposed to corrosive chemicals, high temperatures, and varying pressures. Their ability to withstand oxidation and corrosion ensures the reliability and longevity of critical infrastructure within petrochemical plants, minimizing maintenance and replacement costs.

Durability and Longevity

The demanding conditions within petrochemical facilities require materials that offer exceptional durability. Stainless steel hex bolt, known for their robustness, maintain their structural integrity even when exposed to aggressive chemicals and extreme temperatures. Their longevity ensures the continued operation of essential equipment without compromising safety or productivity, reducing downtime and operational disruptions.

High Temperature and Pressure Resistance

Petrochemical processes often involve high-pressure and high-temperature conditions. Stainless steel fasteners, engineered to withstand such extremes, play a vital role in maintaining the integrity of pipelines, reactors, and various equipment. Their ability to endure these harsh conditions without compromising performance ensures petrochemical facilities’ safe and efficient operation.

Safety and Reliability Standards

Safety is a top priority in the petrochemical industry, and SS stud bolt contributes significantly to meeting stringent safety standards. Their high tensile strength, resistance to stress corrosion cracking, and fatigue resistance make them reliable components in critical applications. This reliability instils confidence in plant operators and regulatory bodies, ensuring the safety of personnel and the surrounding environment.

Reduced Maintenance Costs and Downtime

The implementation of stainless steel fasteners results in reduced maintenance requirements and operational downtime. Their resistance to corrosion and degradation minimizes the need for frequent inspections and replacements, leading to cost savings in maintenance and ensuring continuous production in petrochemical plants.

Environmental Compliance and Sustainability

Stainless steel fasteners align with the growing emphasis on environmental sustainability. Their durability and resistance to corrosion contribute to the longevity of equipment, reducing the frequency of material replacements and minimizing waste generation. Additionally, the recyclability of stainless steel supports eco-friendly practices within the petrochemical industry.

Conclusion

Stainless steel fasteners have emerged as indispensable components in the petrochemical business, offering unmatched corrosion resistance, durability, and reliability. Their ability to withstand harsh environments, high temperatures, and corrosive substances ensures the petrochemical infrastructure’s safety, efficiency, and longevity. As the industry prioritizes safety and operational excellence, stainless steel fasteners are crucial assets, driving reliability and sustainability in petrochemical operations.